Sustainable Supply Chain

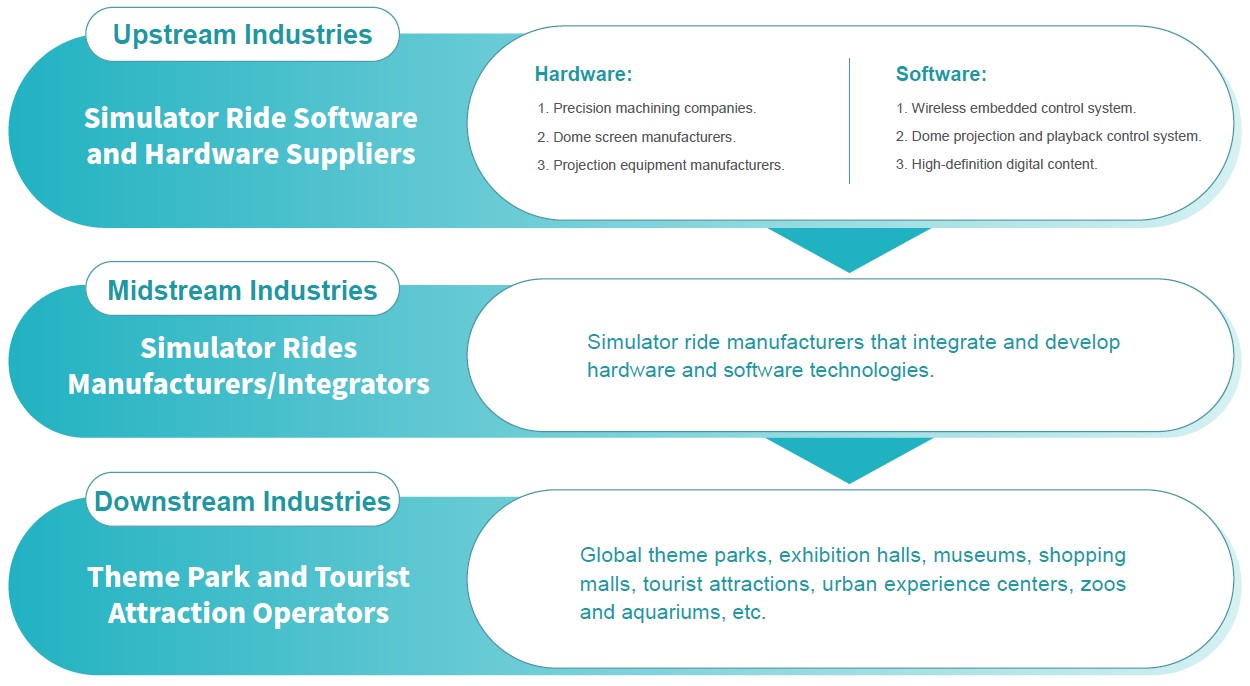

Brogent's simulator rides are developed via the synchronized integration of multiple systems and high-end technologies. To manufacture stable and safe products, mechanical manufacturing, electrical control, audiovisual system, and safety certification system in the upstream industry chain must be integrated to successfully create various new-generation entertainment facilities with the latest form of media.

Brogent has established complete supply chain management regulations and measures, including supplier management principles, new supplier review system, and supplier risk classification, and supplier management (including evaluation and consultation). In addition, Brogent focuses on issues of quality and safety, endeavoring to optimize the supplier cooperation models, guide suppliers to grow together, work together to improve immersive simulation technology, and fulfill CSR to achieve sustainable operations.

Supply Chain Management

Brogent has established complete supply chain management regulations and measures, including supplier management principles, new supplier review system, and supplier risk classification, and supplier management (including evaluation and consultation). In addition, Brogent focuses on issues of quality and safety, endeavoring to optimize the supplier cooperation models, guide suppliers to grow together, work together to improve immersive simulation technology, and fulfill CSR to achieve sustainable operations.

Supply Chain Management

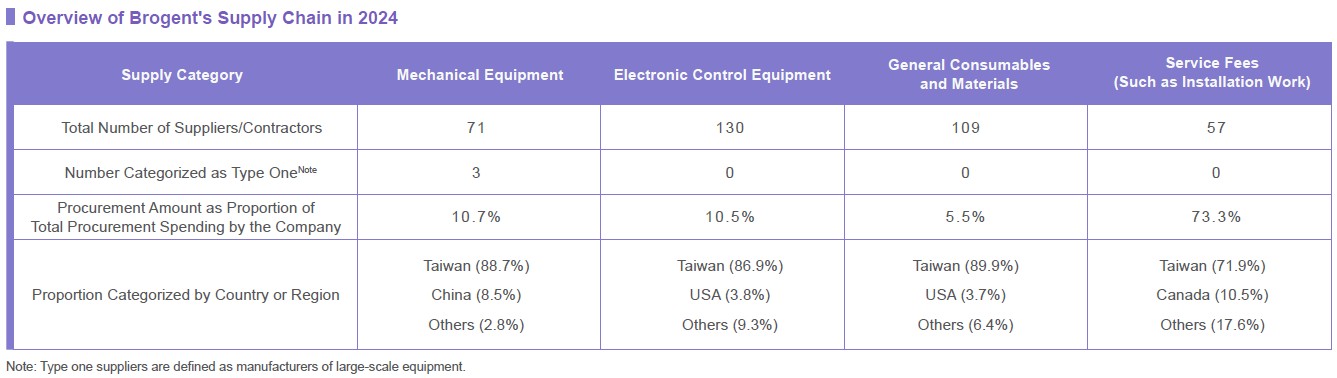

- In 2024, there are 367 transaction suppliers, with Taiwan as the main operating base, accounting for 85.8% of the local procurement amount and 14.2% of the procurement amount from other countries.

- There are currently 1,207 suppliers, in which 83 were added in 2024.

- In 2024, the proportion of labor is higher due to the demand for factory construction and overseas filming.

Supplier Management Principles

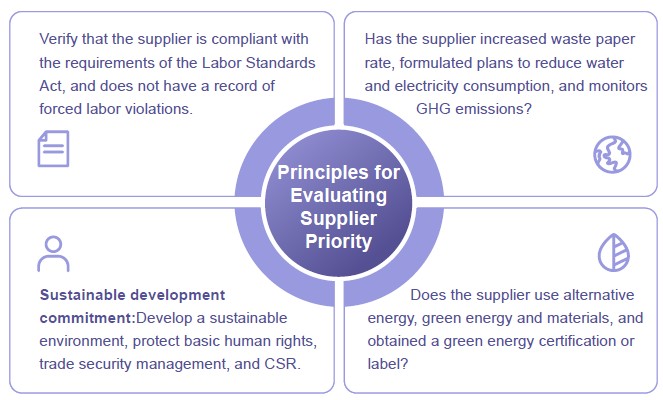

Brogent chooses qualified suppliers and sets Quality, Schedule, and Cost as the three primary factors of the management principles to ensure a steady supply of materials and high-quality engineering. In order to jointly pursue sustainable business operation and growth, we create a win-win sustainable supply chain. Environmental certification or labels are one of the evaluation metrics included in our sustainable supply chain evaluation of suppliers. Suppliers who have obtained these labels would be given preference for being selected. Between suppliers who can provide the same services, priority would be given to suppliers located closer to us, reducing the distance which our employees have to travel and the amount of air pollution generated by product shipping.

Supplier Risk Management

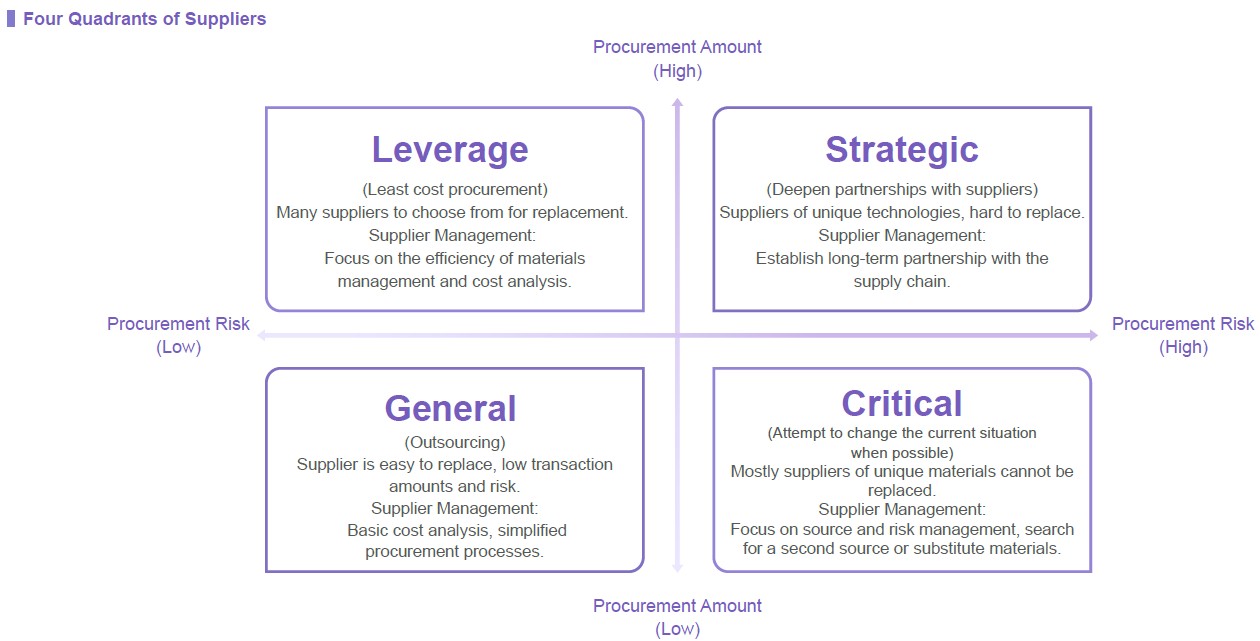

Brogent's suppliers are divided into two categories: general materials and outsourced projects. As of the end of 2024, Brogent has a total of 1,207 suppliers. According to the risk analysis of the purchase management procedure, as well as purchase risks and purchase prices identified in the management procedure, Brogent classifies suppliers into four risk quadrants and applies different management methods accordingly.

In addition, in accordance with the principles for evaluating supplier priority, the risk of forced and compulsory labor incidents occurring in the cooperative suppliers of all Brogent's operating locations is quite low.

Supplier Cooperation Regulations

Brogent's assessment of new suppliers includes a preliminary review process that considers capital, operating conditions, production capacity, and performance. We then determine whether to conduct an on-site inspection and assessment based on the situation. When cooperating with new suppliers, we sign a purchase contract or purchase order based on the situation, and require the supplier to agree to abide by Brogent's sustainable development requirements, including protecting human rights, not using child labor, and prohibiting discrimination and unfair treatment in employment, salaries, and promotions. Suppliers are required to comply with local labor safety and health regulations and provide a safe and healthy working environment.

Supplier Evaluation

Supplier Evaluation and Screening Principles

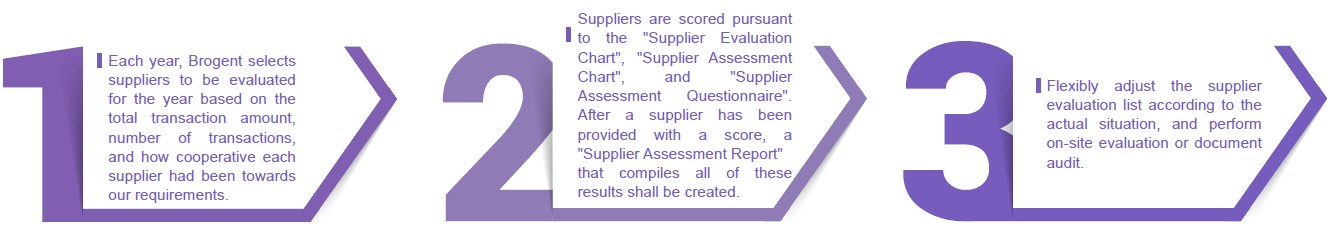

Supplier Evaluation Process

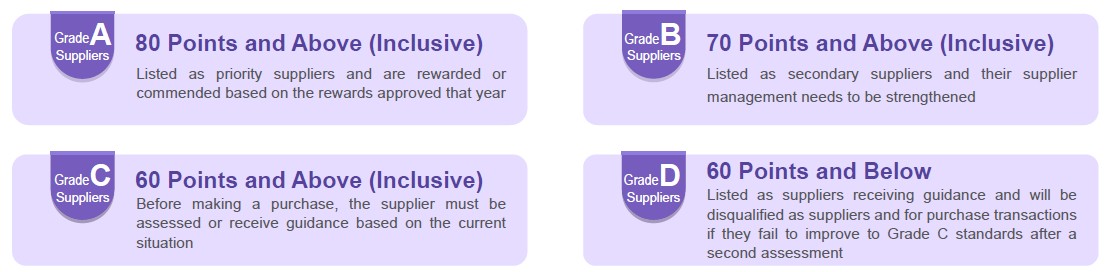

Explanation of Supplier Assessment Grades

ESG Requirements for Supplier Evaluation

Brogent conducts annual supplier evaluations, and in 2024, we start planning additional ESG evaluation questions in the Supplier Evaluation Questionnaire that include human rights issues, such as diversity and inclusion, healthy workplace, reasonable working hours, respect for employees, labor communication, employee training, and privacy protection, etc., in order to ensure that our partner companies comply with the basic human rights protections, as well as respecting the working environment and well-being of their employees; These measures help to raise the ethical standards of the entire supply chain and reinforce our commitment to social responsibility.

Supplier Assessment Grades and Results in 2024

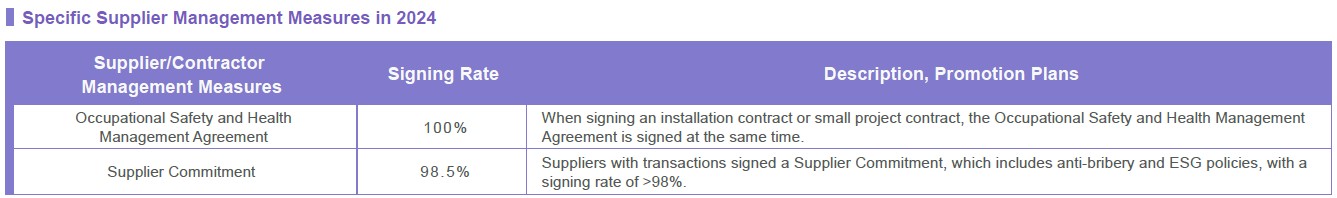

We use two methods for supplier evaluation: electronic questionnaire and annual evaluation. After deliveries are accepted during weekdays, the suppliers are randomly selected to fill out an electronic questionnaire, and the questionnaire recovery rate is > 98%. The 2024 annual ratings were selected based on 2024 transaction data. A total of seven companies were selected, in which four were graded A and three were graded B, with an average score of 79.6.

Supply Chain Strategy for Upgrading Old Suppliers and Cultivating New Suppliers

For the upgrading of old suppliers, we take the approach of cooperating with them starting from small cases and counseling them to meet our requirements in terms of quality, and then gradually undertake large-scale cases; on the other hand, for those suppliers with good qualifications, we will counsel them to obtain internationally recognized qualifications, so as to enable them to undertake cases in various countries. For new supplier cultivation, we have formulated a comprehensive development SOP process to ensure that new partners can be quickly integrated into our supply chain system in all aspects. These strategies not only help to enhance the overall capacity and competitiveness of our suppliers, but also help to promote the long-term stable development of our enterprise.

The Role Brogent Plays in the Immersive Simulation Technology Industry Chain

Brogent has the ability to integrate upstream, midstream and downstream. We design and integrate the upstream software and hardware manufacturers with domestic and overseas technologies according to the needs of customers, and then sell them to downstream customers, providing comprehensive service content and creating a unique immersive simulation technology industry ecosystem.