Innovative Technologies and Contents

Innovative Development Strategy Framework

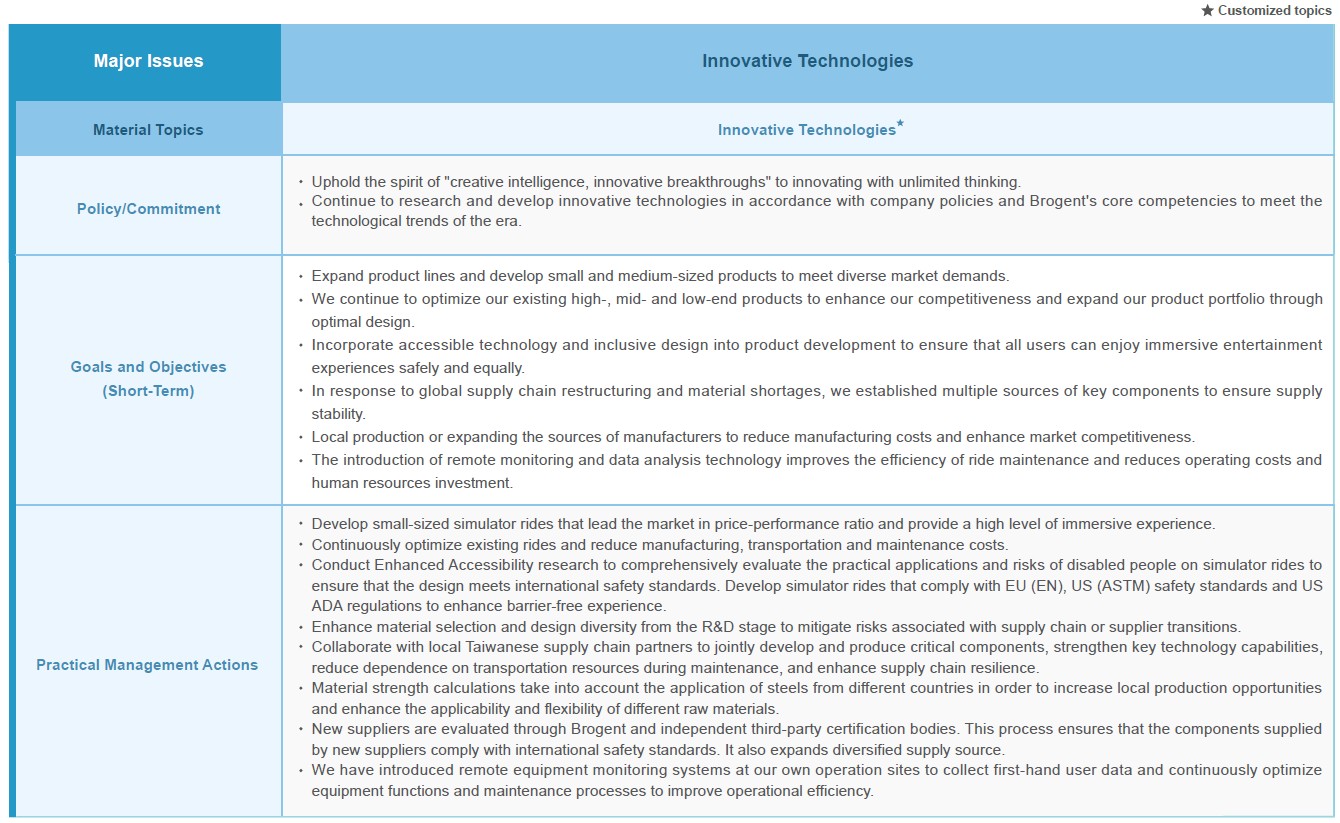

Compared with traditional mechanical equipment, such as roller coasters, immersive experiences are less likely to cause physical injury and social burden due to the pursuit of excitement. Brogent uses simulation technology to create a variety of products that integrate software and hardware, and aims to develop products that improve human life. It is also expected to be able to solve and improve human health and safety problems through the innovative application of immersive simulation technology. Achieving higher social responsibility with years of immersive simulation technological achievement is the original intention of Brogent's continuous technology innovation.Brogent's R&D team needs to continuously engage in innovation and development, and combine technology and diverse applications to launch products that meet market needs. Therefore, the key to designing products that are both entertaining and safe is to let experts in mechanics, electrical control, and audiovisual simulation to work closely together, understanding market demand to maximize revenue for customers.

Innovative Application of Technology

In order to improve the efficiency and quality of R&D and project execution, the Company continues to strengthen the application of AI technology and combine technological strength to enhance product content, including:

- Using AI to develop 4K to 8K technology, the original aerial filming can be directly upgraded, reducing the cost of re-production and resource consumption.

- Develop CGI videos using game engines and use real-time graphics technology to simplify the animation production process to increase the speed of CGI content production. At the same time, digital assets are easy to share, and the program features greatly reduce the manpower investment and time of development.

- Accelerate planning and setting through AI-generated graphics, and provide more diverse thematic content to make the experience more immersive and vivid.

Internal Accumulation of Innovative Energy

1. Education, Training and Professional Development

Brogent is committed to strengthening the professional skills and cross-disciplinary capabilities of its employees. Through a multi-level education and training mechanism, it enhances the competitiveness of the team and ensures that product development and manufacturing meet international standards, ensures that talent training and development meet ESG goals, and supports corporate sustainable operations and innovative development. Training directions include the following areas:

- Core professional training: including mechanical design, electrical control technology and safety standards to ensure that the engineering team has the latest technical knowledge and the ability to comply with international regulatory requirements.

- Cross-disciplinary integration training: Encourage collaboration between different departments and enhance employees’ adaptability and innovative thinking in a multi-professional environment.

- Departmental technical exchange and application:

(1). Mechanical Department: Assigned to the Manufacturing Center to participate in the production process, gain in-depth understanding of the manufacturing process, and ensure a high degree of integration between design and manufacturing.

(2). Mechatronic System Department and Mechanical Department: Collaborate with the Engineering Management Center to go to the project site to participate in ride installation and tuning to ensure a deep understanding of on-site requirements and optimize future designs and applications.

(3). The "R&D and Product Focus Meetings" convenes by the General Manager's Office every month, where the General Manager, sales personnel, and R&D personnel gather to share and discuss the latest technologies and market information.

(2). Mechatronic System Department and Mechanical Department: Collaborate with the Engineering Management Center to go to the project site to participate in ride installation and tuning to ensure a deep understanding of on-site requirements and optimize future designs and applications.

(3). The "R&D and Product Focus Meetings" convenes by the General Manager's Office every month, where the General Manager, sales personnel, and R&D personnel gather to share and discuss the latest technologies and market information.

2. Talent Development and Promotion Mechanism

Promote specific talent development plans, encourage employees to accumulate cross-disciplinary experience and develop management capabilities, and establish the following career paths:

- Senior engineer with cross-disciplinary integration capabilities.

- Advance to R&D manager, responsible for technical management and team collaboration.

- Develop into a product manager, coordinating product design and marketing strategy.

- Further promoted to project planner, participating in corporate decision-making and market layout.

3. Internal Control System Optimization

In order to enhance the efficiency of R&D and project execution, the Company continues to strengthen its internal control system and establish an efficient decision-making and feedback mechanism, including:

- The cyclical feedback mechanism of project preliminary assessment, product planning and R&D management ensures that the development process is systematic and meets market and technical requirements.

- Redefine the division of labor according to the needs of different business situations to enhance organizational flexibility and optimize resource allocation.

External Cross-Disciplinary Innovation Cooperation

The cross-disciplinary collaboration to enhance the effectiveness of Brogent's R&D includes the following areas:

The cross-disciplinary collaboration to enhance the effectiveness of Brogent's R&D includes the following areas:

- We provide R&D personnel with the latest knowledge and technologies of academia through industry-academia collaboration. We also commission academia to carry out projects that require in-depth theoretical research. If the projects produce results, the technology is transferred for commercial product development, thereby maximizing the Company's R&D efficiency. In addition, we can also attract new talents to join the Brogent team in the collaboration process.

- We periodically send R&D personnel to participate in immersive simulation technology related seminars or exhibitions, and visit the latest immersive simulation facilities that are opened.

Innovation and R&D Management

Brogent's R&D technology team is formed by the Technology Center, Product Center, and Content and Design Center, and aims to make more innovative breakthroughs in the simulation technology industry. Brogent regularly plans training and participation in seminars for the R&D team every year to ensure that it is up-to-date on cutting-edge simulation technology issues, trends, and technologies around the world. Moreover, we collaborate with domestic and international organizations to improve our expertise in product development and industrial competitiveness.

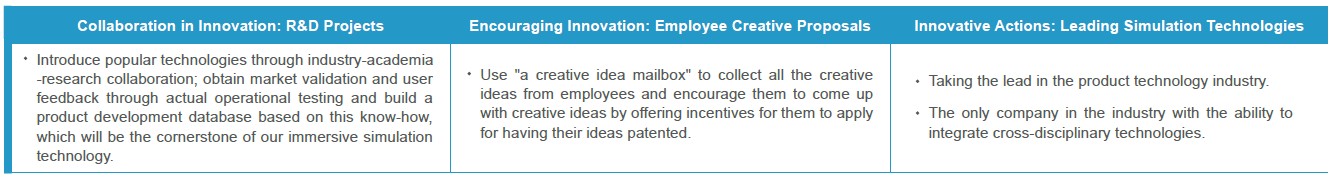

We base our innovation and R&D on project R&D and creative proposals put forward by our employees. A product development database has been built based on the R&D results. We communicate with colleagues across departments on a monthly basis to learn about market and customer demand. After internal discussions and brainstorming, we propose corresponding R&D projects based on the R&D Management Regulations and annual strategies and targets and set up a team for implementation. The departments also encourage employees to share new knowledge about the Company's products through the internal training system to inspire great ideas.

Employees can propose new ideas for products or technology research and development based on the creative proposal management regulations in accordance with the Company's R&D management and annual strategies. After internal review and discussion, they shall be reported to the Company for resource allocation and budgeting for implementation.

We base our innovation and R&D on project R&D and creative proposals put forward by our employees. A product development database has been built based on the R&D results. We communicate with colleagues across departments on a monthly basis to learn about market and customer demand. After internal discussions and brainstorming, we propose corresponding R&D projects based on the R&D Management Regulations and annual strategies and targets and set up a team for implementation. The departments also encourage employees to share new knowledge about the Company's products through the internal training system to inspire great ideas.

Employees can propose new ideas for products or technology research and development based on the creative proposal management regulations in accordance with the Company's R&D management and annual strategies. After internal review and discussion, they shall be reported to the Company for resource allocation and budgeting for implementation.

Stakeholder Participation and Feedback System

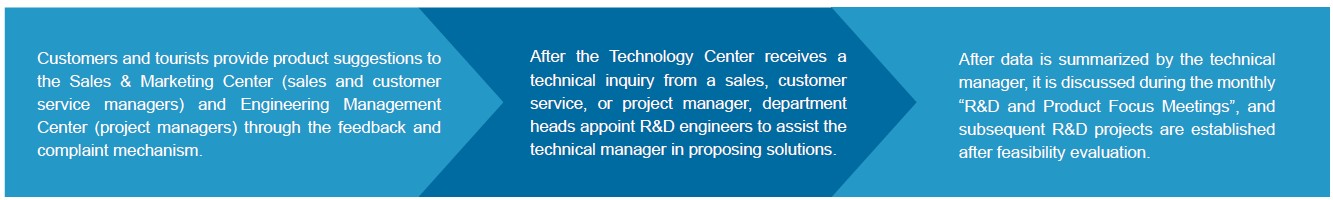

PDM System

Brogent combined the current R&D system with the PDM system for the BOM and ERP systems to be used together, strengthening collaboration for more efficient design. Ongoing projects and R&D projects currently all use the PDM system for graphics/BOM management and document management review and issuance. This optimizes the R&D workflow and allows PDM, data preservation, and intellectual property rights management to be effectively carried out. The scope includes sales, R&D, and evaluation projects. R&D efficiency is greatly improved through management using the PDM system.

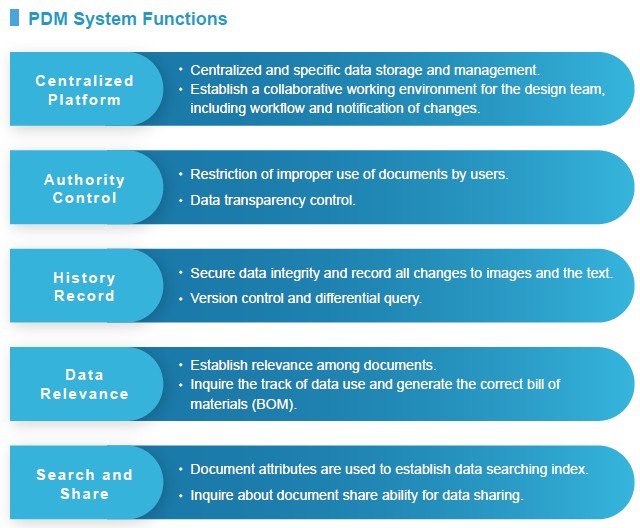

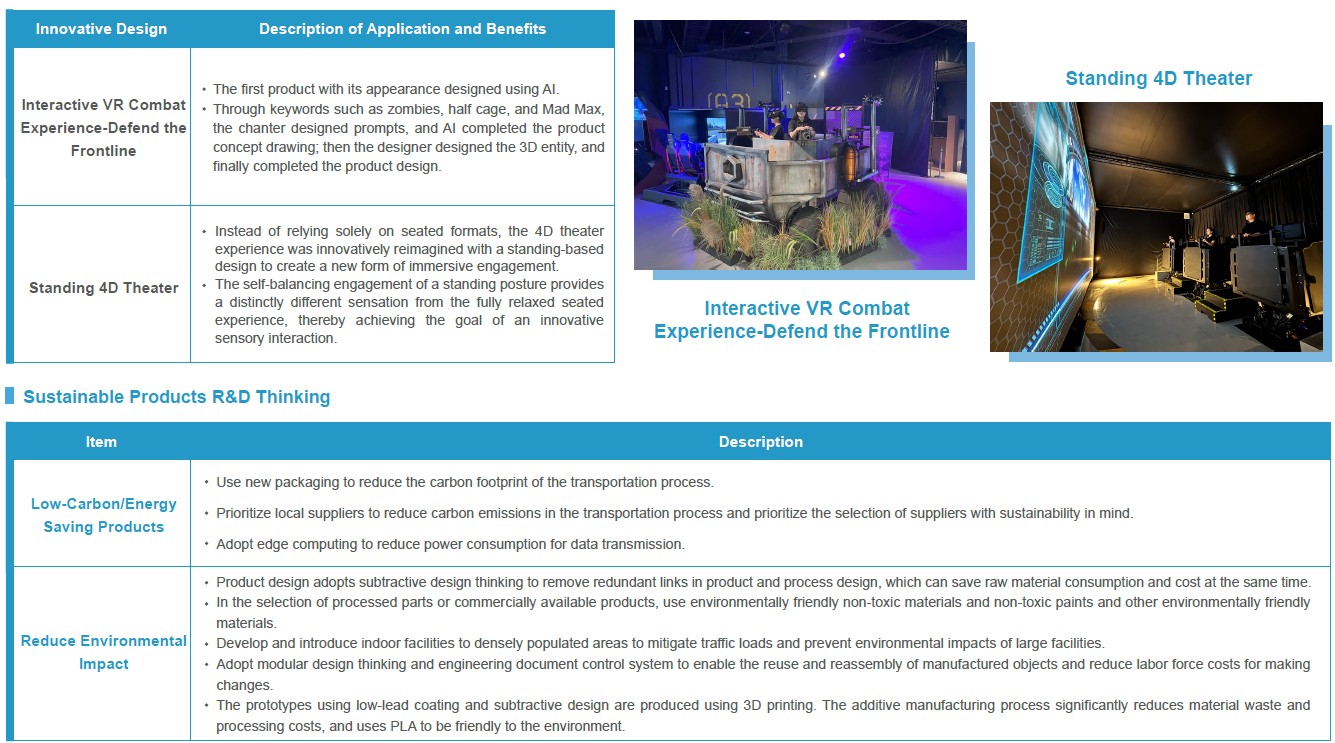

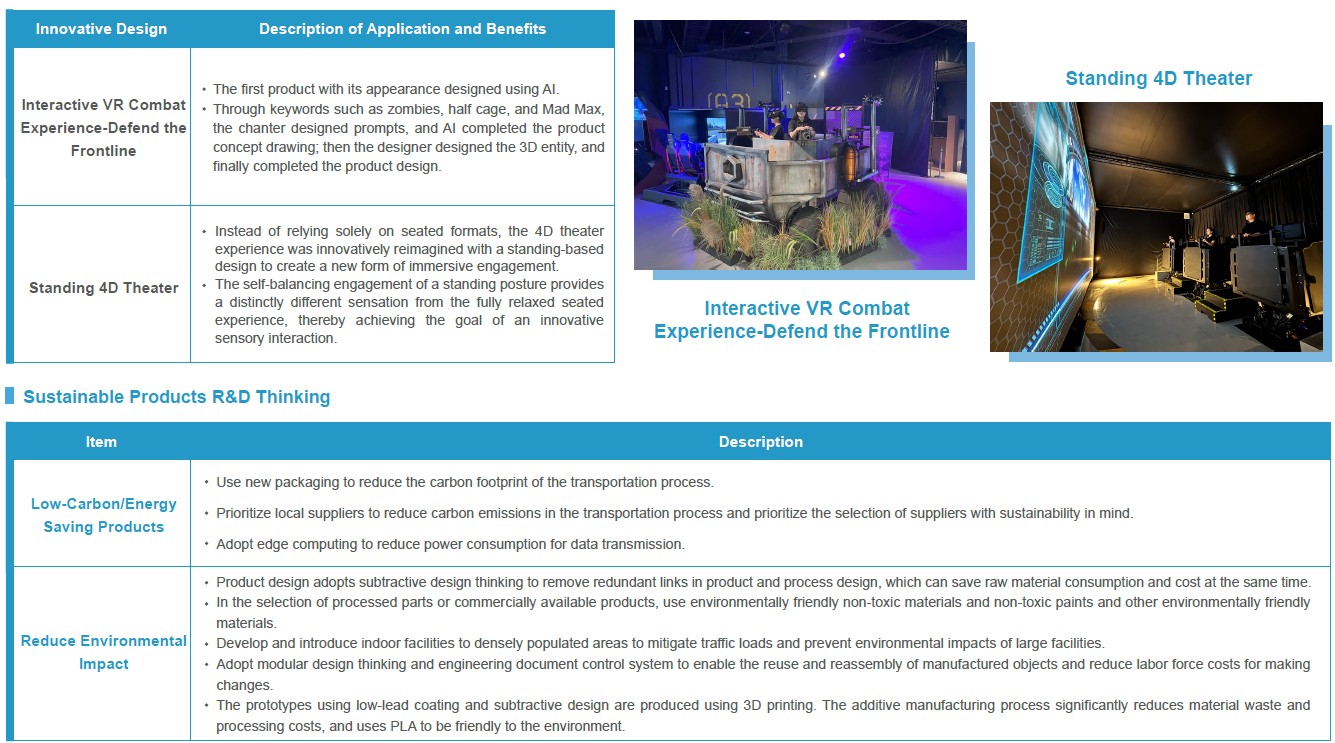

Innovative Design Applications

Brogent adheres to the core philosophy of "creativeness" and encourages employees to incorporate innovative and sustainable design concepts when developing products. We combine our core technologies with new immersive simulation technologies to design a variety of innovative energy-efficient simulator rides with low carbon emissions.

Industry-Government-Academia Research Collaboration

Brogent not only periodically sends R&D personnel to participate in immersive simulation technology related seminars and exhibitions, and visit the latest immersive simulation rides to actively connect its own company with the world, but also commissions academics to assist in academic and theoretical researches, and if there are any results, they will be transferred into commercial product development.

Industry-Government-Academia Research Collaboration

Brogent not only periodically sends R&D personnel to participate in immersive simulation technology related seminars and exhibitions, and visit the latest immersive simulation rides to actively connect its own company with the world, but also commissions academics to assist in academic and theoretical researches, and if there are any results, they will be transferred into commercial product development.

Reliability Analysis of Critical Components Collaboration Project

Cooperating with Joint Research & Development Center of NSYSU and Brogent Technologies, Inc. to improve the reliability and service life of small-sized immersive interactive platforms. Brogent and the Department of Mechanical and Electromechanical Engineering of NSYSU jointly promote a project to build a life model and Mean Time to Failure (MTTF) for critical components, which it provides accurate product life prediction and maintenance recommendations through scientific data analysis to enhance market competitiveness. The implementation of this project will help Brogent formulate more accurate ride life specifications and maintenance strategies, optimize component replacement frequency, further improve product reliability and operational efficiency to ensure market competitive advantage.

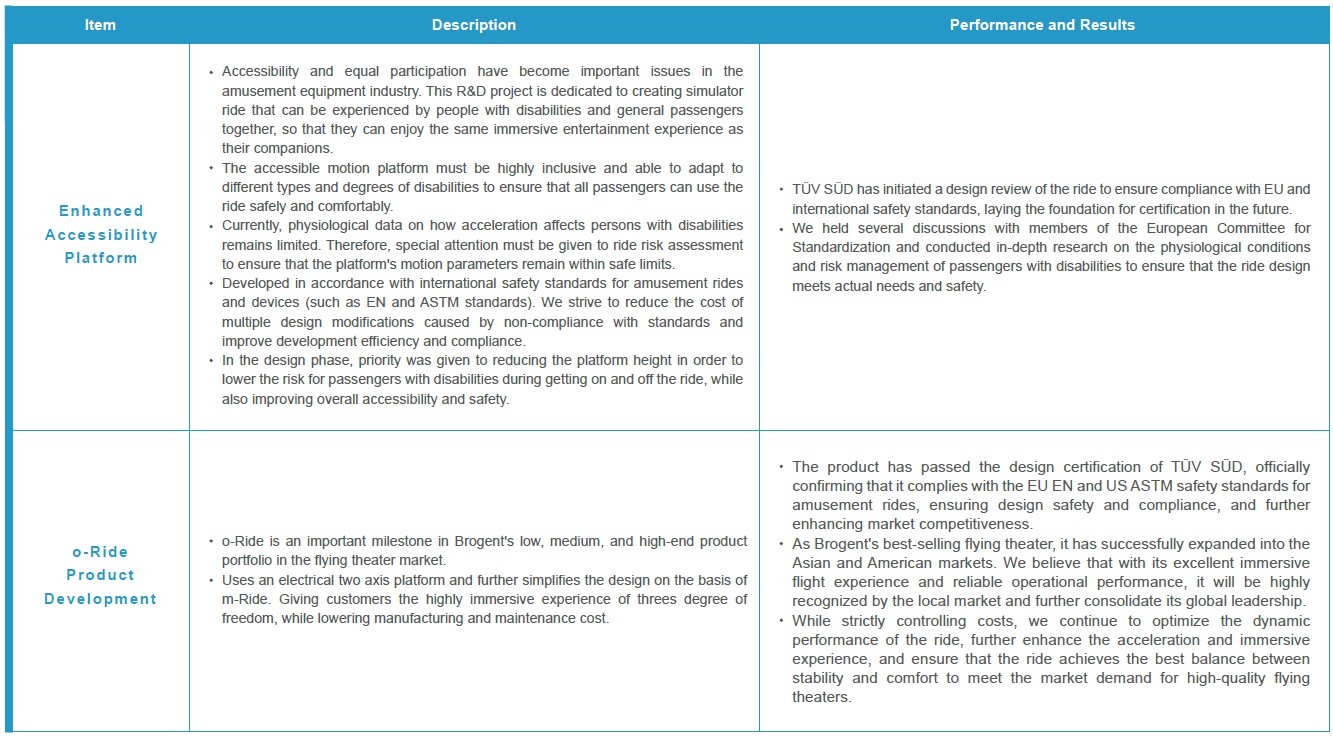

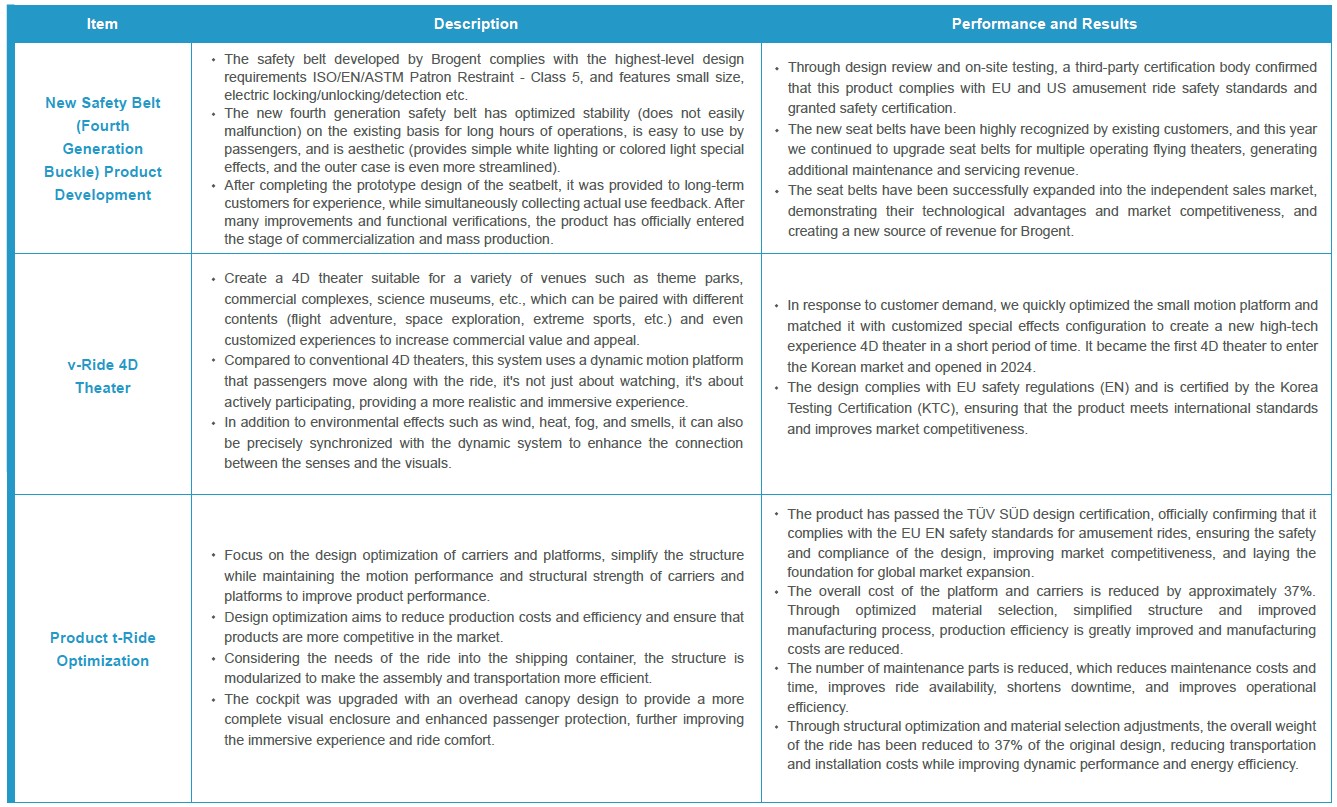

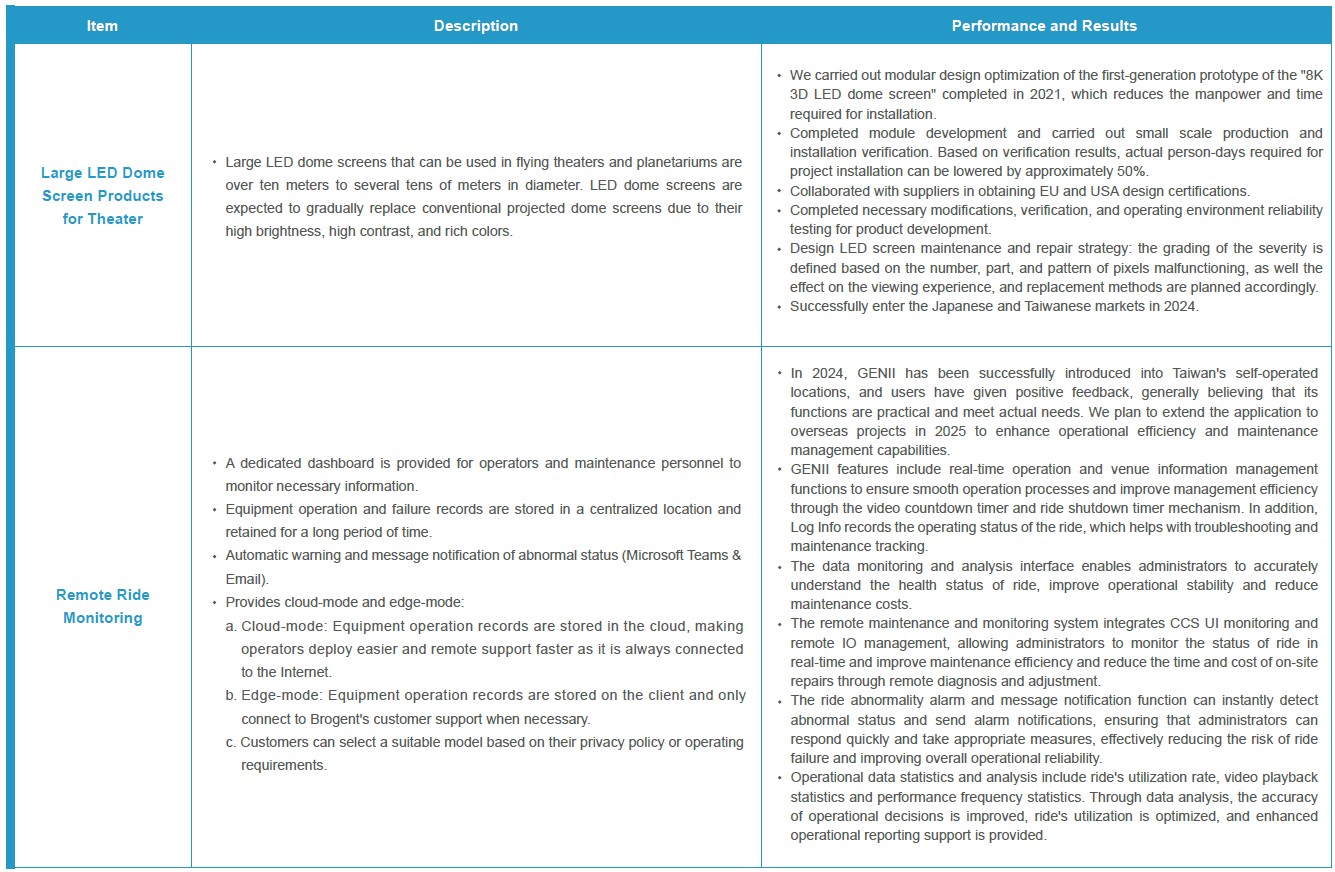

R&D Achievements

Brogent has always spared no effort in R&D, continues to conduct R&D of forward-looking technologies and innovative applications, and implements product design research and systematic management to maintain the leadership of its products and technologies. In 2024, there were 113 R&D personnel, and R&D expenses totaled NT$138,062 thousand, accounting for 11% of the annual revenue that year.